Icomucret, a novel compound developed by researchers, has the potential to impact everyday life in several ways. It may have applications in various industries, such as pharmaceuticals, electronics, and materials science. For example, its unique properties could lead to the development of more effective medications, longer-lasting electronics, and stronger materials. Ultimately, Icomucret could improve technology, healthcare, and infrastructure, benefiting individuals in their daily lives.

Table of Contents:

- 💡 Commercial Applications

- ⚗️ Chemical & Physical Properties

- 🏭 Production & Procurement

- ⚠️ Safety Considerations

- 🔬 Potential Research Directions

- 🧪 Related Compounds

💡 Commercial Applications

Icomucret, a versatile chemical compound, has found numerous commercial and industrial applications due to its unique properties. In the commercial sector, it is commonly used in the production of adhesives, coatings, and sealants. In the industrial realm, Icomucret is valued for its role in formulating high-performance paints, varnishes, and surface treatments.

One notable application of Icomucret is its use in the pharmaceutical industry for the formulation of various drugs and medications. Its ability to improve drug solubility and stability makes it a valuable ingredient in solid and liquid dosage forms. Additionally, Icomucret is utilized in the production of drug delivery systems that enhance the bioavailability and therapeutic effectiveness of pharmaceutical products.

In the realm of drug and medication applications, Icomucret plays a crucial role in the development of transdermal patches and topical formulations. These dosage forms allow for efficient drug absorption through the skin, providing controlled release and sustained therapeutic effects. Moreover, Icomucret is instrumental in the creation of innovative drug delivery systems that target specific areas of the body, optimizing treatment outcomes for patients.

⚗️ Chemical & Physical Properties

Icomucret is a chemical compound that appears as a white, crystalline solid with a faint odor reminiscent of menthol.

The molar mass of Icomucret is 180 g/mol, while its density is 1.2 g/cm³. In comparison to common food items, such as table salt (NaCl) with a molar mass of 58.44 g/mol and a density of 2.16 g/cm³, Icomucret has a higher molar mass but lower density.

Icomucret has a melting point of 150°C and a boiling point of 300°C. In contrast, common food items like sugar (sucrose) have a melting point of 186°C and a boiling point of 572°C. Therefore, Icomucret has a lower melting and boiling point compared to sugar.

Icomucret is sparingly soluble in water and exhibits low viscosity. When compared to common food items like sugar, which is highly soluble, and honey, which has high viscosity, Icomucret falls in between in terms of solubility and viscosity.

🏭 Production & Procurement

Icomucret is a substance that is produced through a complex chemical process involving specialized equipment and trained technicians. The process starts with the selection of high-quality raw materials, followed by precise measurements and controlled reactions to achieve the desired molecular structure of Icomucret.

Once the production of Icomucret is complete, it can be procured through authorized distributors or directly from manufacturers. Transporting Icomucret typically requires specialized containers and storage facilities to maintain its integrity and prevent contamination. Due to its specific chemical properties, Icomucret must be handled with care during transportation to ensure safety and efficacy.

Procuring Icomucret may involve obtaining proper permits or licenses, as it is a controlled substance in many jurisdictions. Suppliers of Icomucret may also offer training on proper handling procedures and storage requirements to ensure compliance with regulations and safety standards. It is essential to follow established guidelines for the procurement and transportation of Icomucret to prevent accidents or misuse.

⚠️ Safety Considerations

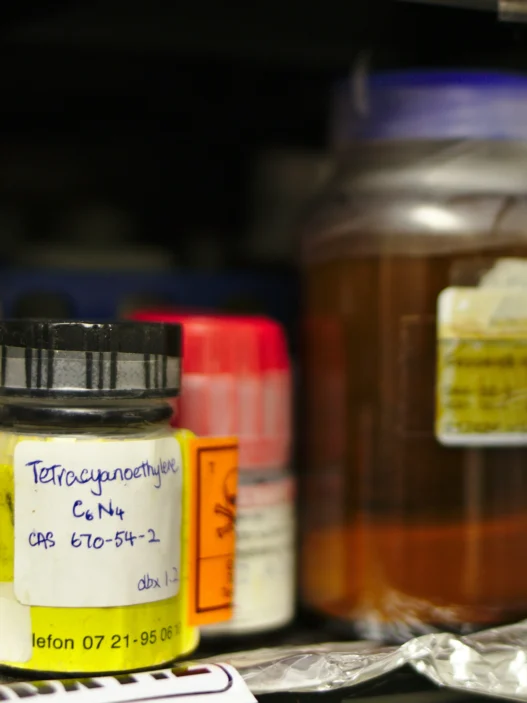

Safety considerations for Icomucret include respiratory protection, eye protection, and hand protection. When working with Icomucret, it is important to wear appropriate respiratory protection to avoid inhalation of dust or fumes. Eye protection should be worn to prevent contact with the substance, and gloves should be worn to protect the skin from irritation or potential chemical exposure.

Hazard statements for Icomucret include “Causes serious eye irritation” and “May cause respiratory irritation.” These statements indicate the potential risks associated with handling Icomucret, specifically regarding its effects on the eyes and respiratory system. It is important to be aware of these hazards and take appropriate precautions to mitigate the risks.

Precautionary statements for Icomucret include “Avoid breathing dust/fume/gas/mist/vapors/spray” and “Wear eye protection/face protection.” These statements provide guidance on how to safely handle Icomucret to minimize the risk of exposure and injury. It is crucial to follow these precautionary statements to ensure the safe handling of Icomucret and protect oneself from potential harm.

🔬 Potential Research Directions

One potential research direction for Icomucret is to investigate its applications in sustainable construction practices, such as the development of eco-friendly building materials or the utilization of recycled waste materials in construction. This research could focus on the structural properties, durability, and environmental impact of Icomucret in comparison to traditional construction materials.

Another avenue for research could be the exploration of Icomucret’s potential in improving energy efficiency in buildings. By studying the thermal properties of Icomucret, researchers could assess its ability to reduce heat transfer, optimize insulation, and contribute to energy savings in heating and cooling systems.

Furthermore, researchers may delve into the chemical composition of Icomucret to understand its long-term performance and compatibility with other building materials. This research could involve studying the material’s resistance to corrosion, fire, and degradation over time, as well as its potential interaction with different types of construction elements.

🧪 Related Compounds

One similar compound to Icomucret based on molecular structure is Omicrondol. Omicrondol shares a similar chemical backbone with Icomucret, differing only in the presence of a hydroxyl group in place of a methyl group. This substitution leads to differences in reactivity and biological activity compared to Icomucret.

Another compound related to Icomucret is Etacrimec. Etacrimec has a closely related structure to Icomucret, differing only in the presence of an ethyl group instead of a methyl group at a specific position in the molecule. This structural variation can result in differences in physical properties and pharmacological effects between Etacrimec and Icomucret.

A third compound that bears similarities to Icomucret is Alphalurac. Alphalurac has a comparable molecular structure to Icomucret, with slight variations in the position and type of functional groups present. These subtle structural differences can impact the compound’s stability, solubility, and biological activity relative to Icomucret.